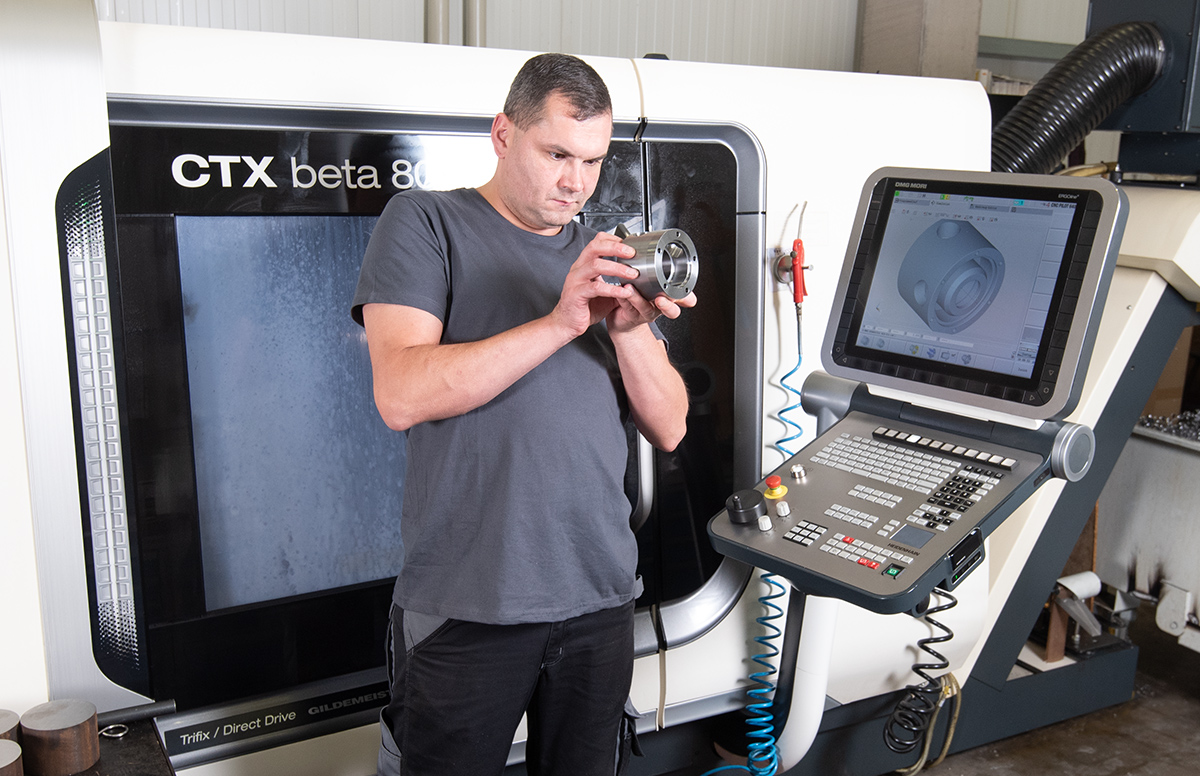

Services

Drilling and broaching

With our broaching machines, we offer conventional processing of workpieces with a groove width of 4.0 to 20.0 mm and a length of up to 200 mm. With conventional drilling, we are able to realize diameters from 1.0 to 40.0 mm.

In the following text we would like to briefly inform you about the two manufacturing processes.

Drilling and broaching are two important manufacturing processes in machining technology that enable precise machining of workpieces. Both processes have their own characteristics and applications.

- Drilling is a process in which a workpiece is machined using a drill with a cutting tip. The drill creates a hole in the workpiece by cutting the material through rotation and pressure. Drilling is often used to make precise holes for screws, pins or other fasteners.

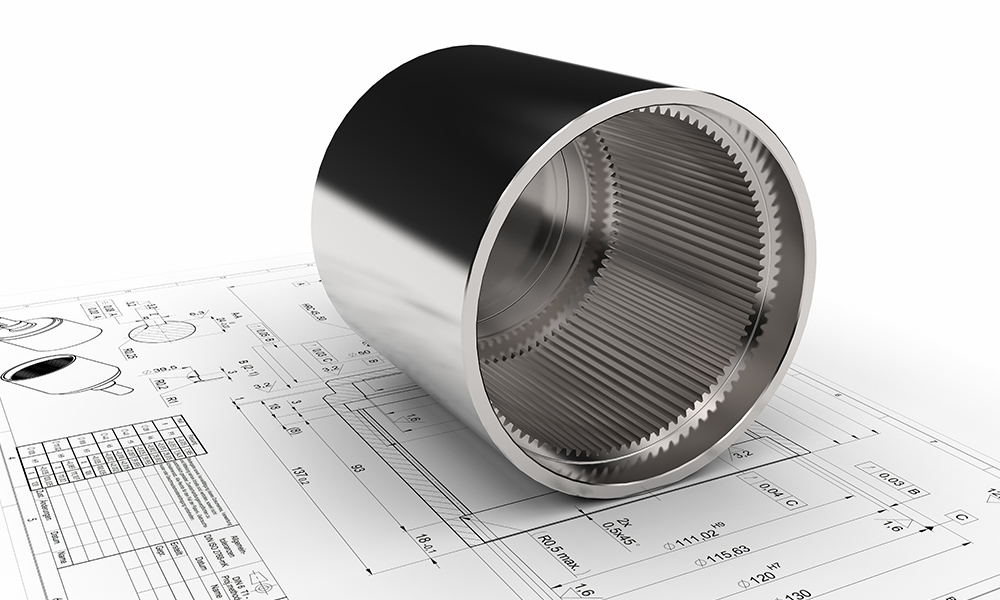

- Broaching, on the other hand, involves machining a workpiece using a broach to create precise and smooth surfaces. The broach consists of several cutting edges that remove excess material and leave a clean surface. Broaching is often used for the production of high-quality workpieces where tight tolerances and a high surface quality are required.

Drilling and broaching with maximum precision – for optimum results and absolute accuracy of fit.

Both processes benefit from high-quality tools, such as carbide drills and carbide broaches, which offer a long service life and wear resistance. Choosing the right tool material is crucial to achieving optimum results.

Drilling and broaching are versatile manufacturing processes that are used in various industries such as automotive, aerospace, medical and many others. Through precise machining, they enable the production of complex shapes, tight tolerances and a high surface quality.

Overall, drilling and broaching play a decisive role in machining technology. The application of these processes requires specialist knowledge, high-quality tools and consideration of the specific requirements of the workpiece to be machined.