Services

CNC turning

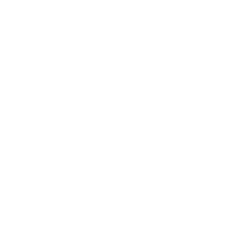

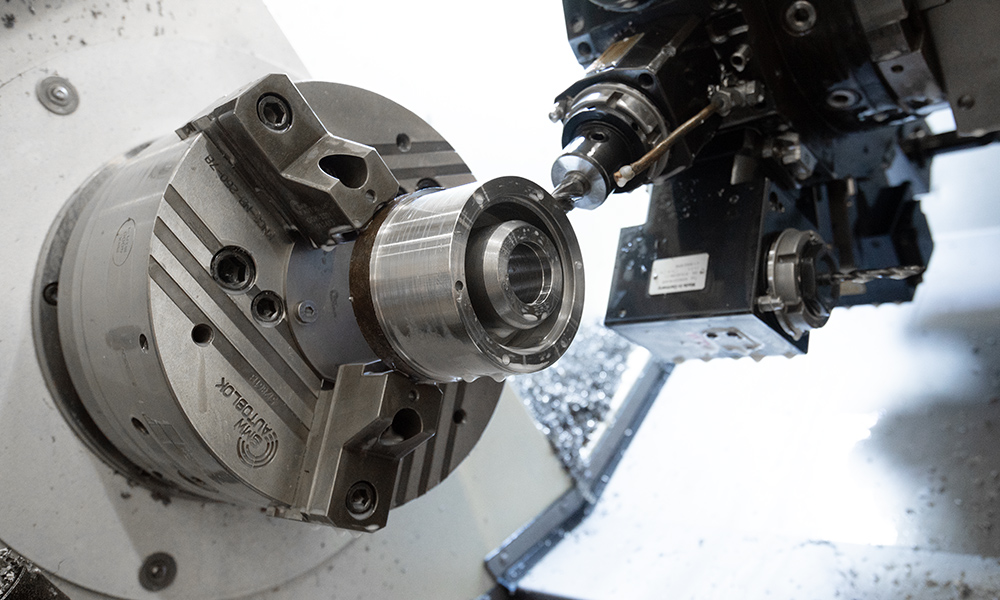

We specialize in the manufacture of a wide variety of workpieces and components using conventional and computer-controlled (CNC) turning processes. We use CNC lathes that enable us to machine complex parts precisely, accurately and within the tightest tolerances. We rely on experienced employees who have the necessary know-how, many years of experience and the ambition to solve even the most unusual tasks to ensure that this is achieved continuously and reliably.

In addition to the production of workpieces and parts, we also offer their design on commission. In the following text we would like to inform you about the different types of turning. Specifically, you will find details on the turning processes of facing, round turning, screw turning, hob turning, profile turning and form turning.

Alongside drilling, milling and grinding, turning is one of the most important manufacturing processes in machining technology. Furthermore, turning is a central process in mechanical and plant engineering that requires extremely high precision. We offer you these forms of turning:

Facing is a form of turning in which the workpiece rotates along a horizontal axis while a cutting tool machines it. This method is often used to create flat surfaces or to reduce workpieces to a certain thickness.

For round turning, a workpiece is rotated in a clamping device while a cutting tool machines it from the side. This process enables the creation of cylindrical shapes, such as shafts or bolts.

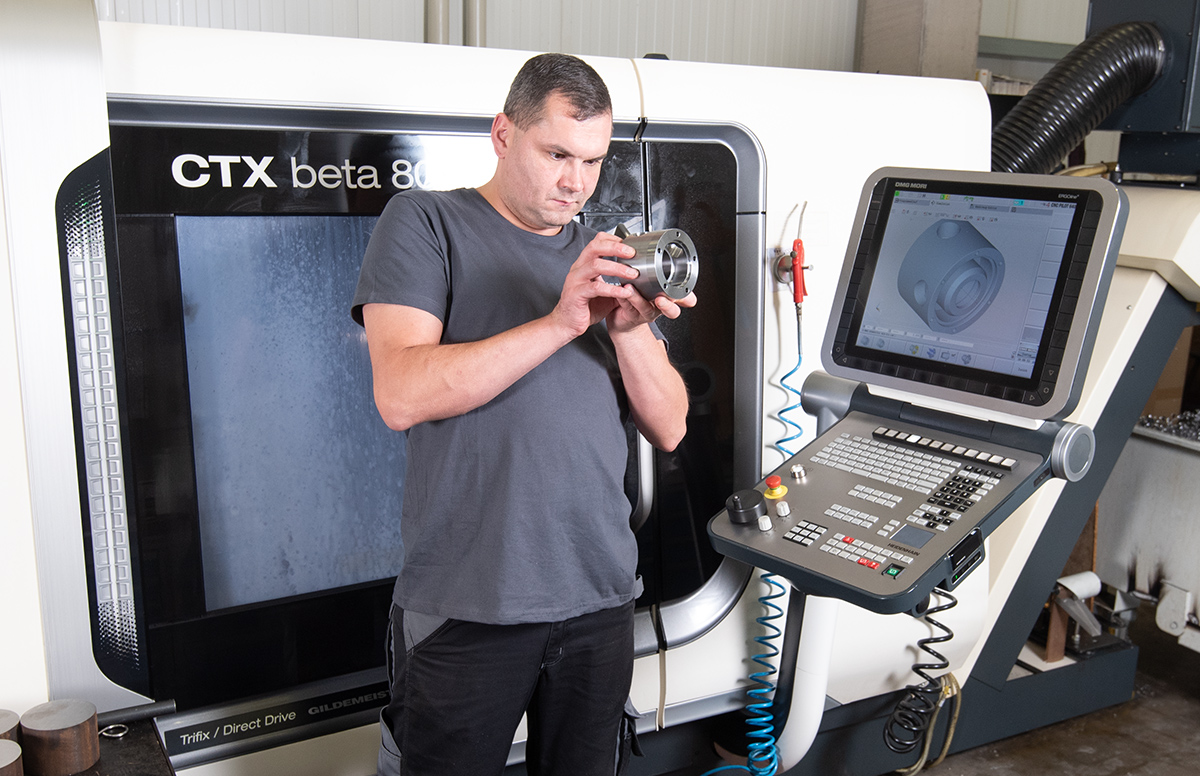

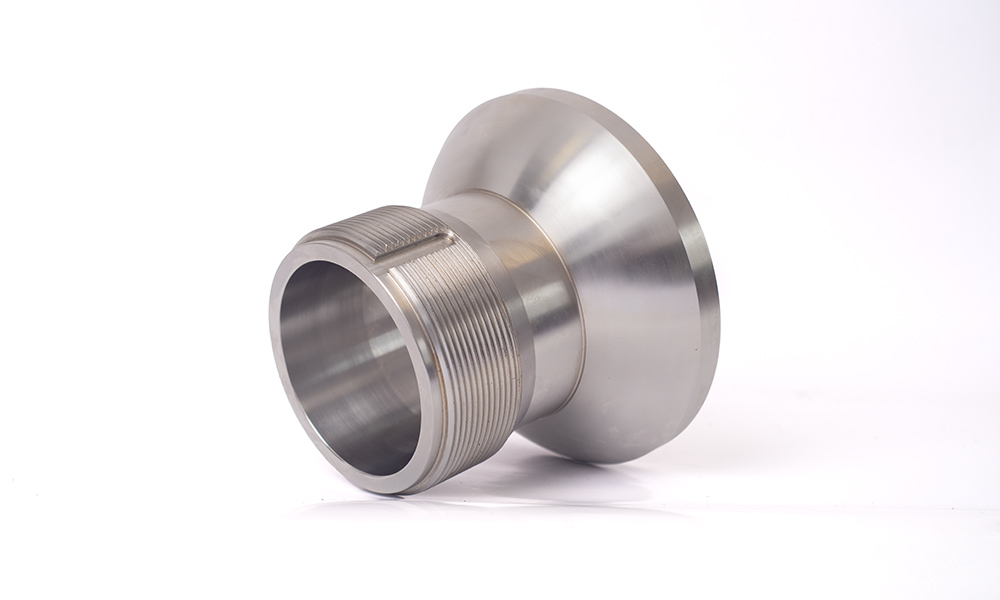

Screw turning is a variant of turning in which the workpiece rotates along an inclined axis. This technique can be used to create threads on workpieces, which is particularly common in metalworking.

Hob turning is a process in which the workpiece is clamped between two rollers and rotated while a cutting tool machines it. This method is often used to produce balls, cams and cylinders.

In profile turning, the workpiece is held in a special clamping device while a cutting tool cuts the desired shape into the workpiece. This allows complex geometric profiles to be created, such as gear teeth or curves.

Form turning is a technique in which the workpiece is shaped into the desired form using a template or forming tool. This process is often used to produce individual or special parts where high accuracy and repeatability are required.

In the CNC sector, we offer machining diameters from 3.0 to 400.0 mm and lengths of up to 1,000 mm.

Regardless of the turning process chosen, maximum precision and experience are crucial in order to meet the requirements of mechanical and plant engineering. Industrial turning enables the precise machining of workpieces and the production of components with tight tolerances to ensure optimum performance and functionality.

We use CNC lathes to machine complex parts precisely, accurately and within the tightest tolerances.

In the conventional range, diameters from 3.0 to 580.0 mm and lengths of up to 1,800 mm are possible.