Services

HSC milling, HPC milling and CNC milling

We offer various milling processes. We would like to inform you about them here and give you a brief overview. Basically, industrial milling in mechanical and plant engineering enables maximum accuracy of fit and precision in the machining of various materials. Milling processes can be used to create complex shapes and contours in workpieces. An important aspect of milling is the cutting geometry. A distinction is made between pointed and undercut milling cutters.

Point-toothed milling cutters: Point-toothed milling cutters can be used for almost all milling work. They are predominantly used.

Undercut milling cutters: Undercut milling cutters are used for form milling. In contrast to pointed cutters, these cutters tend to be used for special applications and are therefore much less common.

HSC milling (high-speed cutting) is characterized by high feed and cutting speeds. It enables efficient material removal with low heat generation and therefore low distortion of the workpiece. This process is particularly suitable for machining hardened materials and light metals.

The aim of HPC milling (High Performance Cutting) is to increase productivity while at the same time increasing tool life. By using special milling tools and optimized cutting parameters, effective chip removal is achieved with low tool loads. HPC milling is ideal for machining tough materials and enables high metal removal rates.

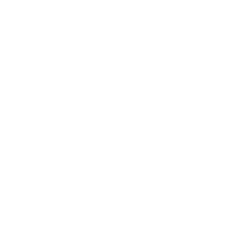

With our modern milling machines, we can implement a wide range of specifications.

CNC milling (Computerized Numerical Control) is an automated milling technique in which the milling movements are precisely controlled by a computer control system. This enables the production of complex shapes and the repeatability of milling processes. CNC milling offers a high degree of flexibility and accuracy in production.

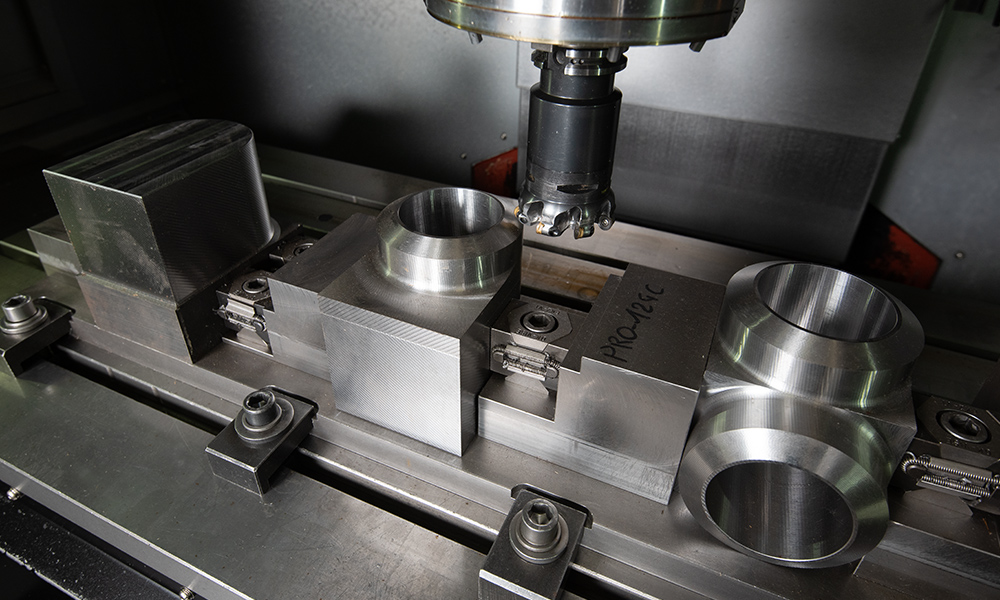

There are different types of milling, including face milling, slot milling, contour milling and form milling. Each of these types has specific areas of application and enables the machining of workpieces with different shapes and geometries.

Depending on the application, we use the appropriate milling tools of the types N, H and W described in DIN 1836.

In the CNC area, we offer a path length of 1067 x 610 x 610 mm (X, Y, Z).

In summary, industrial milling in mechanical and plant engineering enables maximum accuracy of fit and precision in the machining of workpieces. With processes such as HSC milling, HPC milling and CNC milling, we can produce complex shapes for you. The various types of milling machines offer flexibility and versatility in production.